ODM Evaporation Residue Testing|100 degree evaporation residue : discounter This test method covers the determination of dissolved organic and inorganic matter and colloidal material found in high-purity water used in the semiconductor, aerospace, and other industries. . WEB26 de nov. de 2020 · Md: Kate Kuray #KateKuray #KateKuray@female_model Поблагодарить можно через VK Pay или здесь: https://vk.com/app6471849_-107647545

{plog:ftitle_list}

8:25. Garota gostosa esguichando no quarto. 37.9K views. 90%. See 99Anjinhatatuada's newest porn videos and official profile, only on Pornhub. Visit us every day because we .

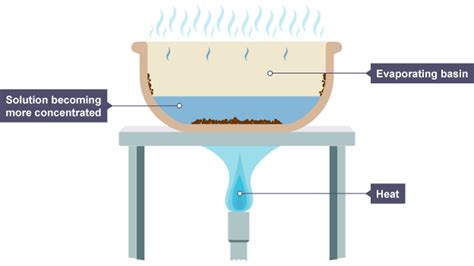

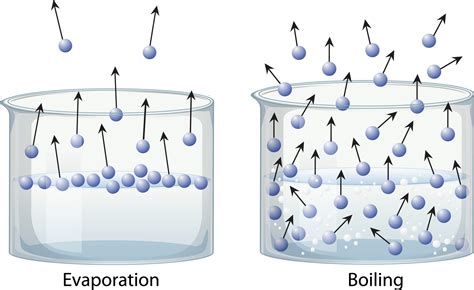

Summary of method. 2.1 A volume of filtered sample that will yield less than 200 mg residue is evaporated just to dryness on a steam bath. The residue is dried at 105°C for 2.0 h, cooled in a desiccator, and immediately weighed.Standard Test Method for On-Line Measurement of Residue After Evaporation of High-Purity Water1 This standard is issued under the fixed designation D 5544; the number immediately .Summary of method. 2.1 A volume of filtered sample that will yield less than 200 mg residue is evaporated just to dryness on a steam bath. The residue is then dried at 180°C for exactly 2 .

This test method covers the determination of dissolved organic and inorganic matter and colloidal material found in high-purity water used in the semiconductor, aerospace, and other industries. .

Scope. 1.1 This test method covers the determination of dissolved organic and inorganic matter and colloidal material found in high-purity water used in the semiconductor, . 12.0 RESIDUE ON EVAPORATION: Evaporate 100 ml of sample to dryness on a water-bath and dry to constant weight at 105°C. The residue weight not more than 1 mg .Gravimetric determination of NVR content measures solvent purity/surface residues to ensure quality and process efficiency. Non-Volatile Matter determination involves evaporating the .

For cleaner residues, selecting the proper detection method involves choosing a specific or non-specific methodology. Specific methods test for an individual ingredient include .3.1.1 carbon residue, n—the residue formed by evaporation and thermal degradation of a carbon containing material. 3.1.1.1 Discussion—The residue is not composed entirely of carbon but is a coke that can be further changed by carbon pyrolysis. 4. Summary of Test Method 4.1 A weighed quantity of sample is placed in a glass vialThe Japanese Food Sanitation Act designates the evaporation residue test as a specification for plastics that intended to contact with foods. The test conditions and migration limits for oils and fatty foods were considered on the basis of the results obtained from the evaporation residue test according to the Japanese Act and the overall migration test into olive oil according to .Categories: Evaporation Residue Testing Overview ERT-01 Evaporation Residue Constant Weight Tester is professionally designed for the precisely quantitative determination of dissolved substances of table wares, containers, packaging films, cans, tubes and other food-use equipments in different soaking solutions.

3.2 This test method for residue by evaporation tends to give an asphaltic residue lower in penetration and ductility than the distillation test method (D6997).Material may be accepted but shall not be rejected as failing to meet specifications containing requirements for determination of residue by distillation, on data obtained by evaporation.

solids on evaporation method

An official website of the United States government. Here's how you know3.2 This test method for residue by evaporation tends to give an asphaltic residue lower in penetration and ductility than the distillation test method (D6997).Material may be accepted but shall not be rejected as failing to meet specifications containing requirements for determination of residue by distillation, on data obtained by evaporation.

tears of a tiger summary test chapters 1 22

MODEL : HGT 915 & 917: Gum Test; SPECIFICATION : Measure evaporation residue in aviation fuels, motor gasolines, and other volatile distillates. > The HGT 915 uses air evaporation, while the HGT 917 offers the versatility of either air or steam evaporation. > Both models are capable of testing three 100 ml samples simultaneously.Going Deeper - Nonvolatile Residue - NVR Testing. While particulate contamination physically blocks openings and clearances, nonvolatile residue (NVR) causes issues through chemical means. . The Critical Role of Flash Evaporation in NVR Testing. A flash evaporator system enables key aspects of NVR testing essential for reliable and accurate .Evaporation Residue Tester can test the dissolving-out amount of test sample soaked in specified liquid. Applications. Applications. Applicable to tableware, food containers, packaging films, bags, cap sealing rubber pad, painted coating for inner wall of cans or tins, plant fiber container and so on made from polyethylene, polystyrene .

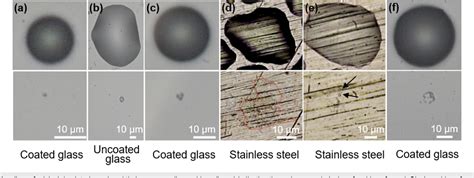

The NaOH they add to it is to prolong shelf life. And the reaction by which sodium hypochlorite is reduced to sodium chloride consumes protons, producing even more hydroxide, so it's indeed possible that residual alkali is causing the irritation the OP is describing.Evaporation residue test (Overall migration test) Limit: 30 μg/ml (when using heptane, PE and PP ≤ 150, PS ≤ 240, PMP ≤ 120 μg/ml ) Determination: Weigh residue of migrant after drying and heating at 105°C for 2 hr. Test condition Food Simulant Temp(°C) Time(min) Normal(pH>5) water . We found that during evaporation, droplets on the tested surfaces first shrink in height (constant contact radius mode) and then in diameter (constant contact angle mode) to form a thin liquid film, leaving behind residues of different types on the order of micrometers, as illustrated in Fig. 1.We either obtain a single residue, most likely a thin film or droplet, or .

residue on evaporation method

3.1 The test may be used to indicate compositional charac-teristics of emulsified asphalt. Evaporation residue may also be subjected to other characterization tests. 3.2 This test method for residue by evaporation tends to give an asphaltic residue lower in penetration and ductility than the distillation test method (D6997). Material may be . Incineration of oil residue (sludge) in Incinerator. Example #7: Burning of oil residue (sludge) in Boiler. Example #8: Evaporation of water (disposal) from an oil residue (sludge) tank listed under items 3.1 in the Supplement to the IOPPC. Example #9: Regeneration of fuel oil from oil residue (sludge)

Drug incineration residue limit is generally 0.1% to 0.2%, according to the drug specified in the incineration residue limit to determine the amount of test samples taken. If the limit is 0.1%, sampling about 1 g; if 0.05%, sampling about 2 g; in more than 1%, sampling can be in 1 g or less. Residue on Evaporation Test (water analysis) : Evaporate 100 ml to dryness on a water bath and dry to constant weight at 105°C. The residue weighs not more than 1 mg (0.001%). Heavy Metals Test (water analysis) : Determined by Method D on 12 ml of a solution prepared in the following manner.

3.1.1 For deÞnitions of terms used in this test method, refer to Terminology D4175. 3.2 DeÞnitions of Terms SpeciÞc to This Standard: 3.2.1 existent gum, nÑthe evaporation residue of aviation fuels, without any further treatment. 3.2.2 solvent washed gum content, nÑ the residue remaining when the evaporation residue (see 3.2.3) has been .

observed or calculated, expressing the result of a test or analysis, shall be rounded off in accordance with IS 2:1960 ‘Rules for rounding off numerical values (revised)’. The number of significant places retained in the rounded off . Tests on residue: t ) Residue by evaporation, 60 percent, A4in 2) Penetration25°C/ 100g/ 80-150 5 sec 3 . The term “SAP” in the context of acetic acid glacial testing likely refers to the “Saponification Value” or “Saponification Acid Value.” The Acetic Acid Glacial Testing Procedure (SAP) saponification value is a measure of the average molecular weight of all the fatty acids present in a substance. It is often used in the analysis of fats and oils.

This test method covers the determination of non-volatile matter, that is, residue on evaporation, in solvent extract from aerospace components, using a rotary flash evaporator. The summary of the test method, the apparatus for testing, reagents and materials for testing, and procedure for testing are all presented in details.CO2 transmission rate test by weighing method: Water vapor transmission rate test by inverted cup method: Non-destructive test for packaging seal performance: Multi-station packaging pressure test: Tensile test of packaging materials with ultra-long elongation: Heat-seal strength test for cap films of medical bottles, yogurt cups and jelly cups

CD Formulation provides loss-on-drying testing to determine the amount of volatile substances in tablets, capsules or bulk materials.CD Formulation offers a one-stop service for testing the physical and chemical parameters of drugs, providing a rapid response to your testing needs and a credible test report.. About Loss on Drying of Drugs. Loss-on-drying (LOD) is determined by .

100 degree evaporation residue

Cleaning validation procedures are carried out in order to assure that residues of cleaning agents are within acceptable limits after the cleaning process. Cleaning agents often consist of a mixture of various surfactants which are in a highly diluted state after the water rinsing procedure has been completed. This makes it difficult to find appropriate analytical methods that are sensitive .6.Now weigh each beakers along with the rods & residue. This will be in grams(A) CALCULATION. Residue, percent = 2 (A – B) where, A = mass of beaker, rod and residue, in g; and B = tare mass of beaker and rod, in g. For the accuracy of the result take the average of them in %. TESTS ON RESIDUE. From this emulsion residue we can perform the .

CO2 transmission rate test by weighing method: Water vapor transmission rate test by inverted cup method: Non-destructive test for packaging seal performance: Multi-station packaging pressure test: Tensile test of packaging materials with ultra-long elongation: Heat-seal strength test for cap films of medical bottles, yogurt cups and jelly cupsThe test: Residue on evaporation according to European Pharmacopoeia 07/2022:0002 – GMP conditions, n°/. is determined by /.. Specimens must be taken using specialist equipment. Samples are collected on/in: Waterproof and inert vial. For this test the lab follows the following method: European Pharmacopoeia 07/2022:0002 – GMP conditions.

Extractable analysis of rubber stoppers for pharmaceutical applications

tears of a tiger test 1

tears of a tiger test 1 answers

graphic designer with a knack for branding and creative visual systems

ODM Evaporation Residue Testing|100 degree evaporation residue